John Deere Rate Controller 2000

Rate control refined

Overview

Reduce rate controller costs

Reduce the cost of purchasing multiple rate controllers by adjusting both liquid and dry products simultaneously with a single controller.

Features

The John Deere Rate Controller 2000 is a drop in replacement for GreenStar™ Rate Controller equipped implements using the GreenStar 3 2630 Display, 4600/4200 Gen 4 CommandCenter™ Displays and 4640/4240 Universal Displays. As a drop in replacement, it uses existing extension and product harnessing plus an adapter cable available in the attachments Price Page.

John Deere Rate Controller 2000 also allows the GreenStar 3 2630 Display, 4600/4200 Gen 4 CommandCenter, and 4640/4240 Universal Displays to integrate with many different liquid or dry product application implements. Examples range from anhydrous ammonia (NH3) applicators, such as the John Deere 2510 Series, self-propelled sprayers, and liquid fertilizer applicators to dry box spreaders, air carts and strip till applicators to accomplish the following:

- Simultaneous liquid and dry product control

- Automatic rate control

- Field documentation

- Map-based prescriptions

- John Deere Section Control (activation required)

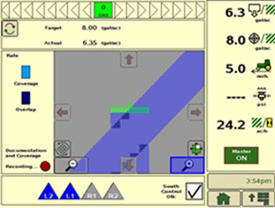

John Deere Section Control activation

John Deere Section Control activationThe John Deere Rate Controller 2000 is compatible with John Deere Section Control to minimize overlaps, reduce input costs, and decrease operator fatigue. With John Deere Section Control enabled, the GreenStar™ 3 2630 Display, 4200/4600 Gen 4 CommandCenter™ Display, and 4240/4640 Universal Displays will automatically shut off the product metering systems when the machine travels into an area that has previously been applied or defined by interior/exterior.

The John Deere Rate Controller 2000 supports the documentation of up to four product applications on the GreenStar 3 2630 Display and five products on 4200/4600 Gen 4 CommandCenter, and 4240/4640 Universal Displays. They can also be configured to run map-based prescriptions for variable rate applications. The John Deere Rate Controller 2000 is able to run a separate prescription for each of the product applications simultaneously.

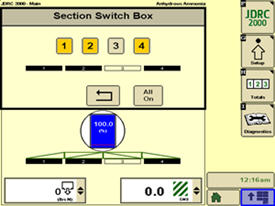

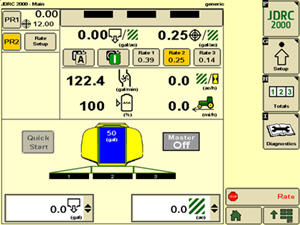

On-screen switch box

On-screen switch box

John Deere Rate Controller 2000 offers an integrated on-screen switch box making manual control of sections easy and quick. John Deere Section Control turns on and off implement or sprayer boom sections based on global positioning system (GPS) and field coverage, in an effort to reduce overlap in headland areas and oddly shaped fields.

John Deere Rate Controller 2000 section compatibility:

SINGLE PRODUCT APPLICATIONS

| Sprayers/liquid fertilizer tool (three wire valves) | Sprayers/liquid fertilizer tool (two wire valves) | Sprayers/liquid fertilizer tool – Tiered boom (three wire valves only) | |

| One product only | 16 | 8 | 20 total |

MULTIPLE PRODUCT APPLICATIONS

| NH3 tool configurations | Spreaders | Air cart/generic | |

| One product | 10 | 12 | 16 |

| Two products | 14 | 12 | 16 |

| Three products | 14 | 12 | 16 |

| Four products | — | 12 | 16 |

| Five products | — | 12 | 12 |

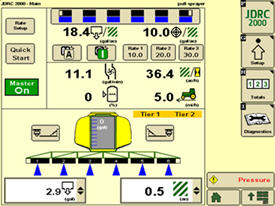

Some pull-type sprayers have a dual-boom or tiered-boom design in order to allow a wider range of speed and application rates.

Flow-based control allows more efficient applications during spraying operations, especially when a second boom is incorporated on the machine.

The John Deere Rate Controller 2000 is able to control these systems.

The John Deere Rate Controller 2000 is compatible with non-John Deere multi-tank air carts. The John Deere Rate Controller 2000 can be configured as an air cart implement type and eliminates the need for a third-party controller. John Deere Rate Controller 2000 is capable of controlling up to five tanks/products and rpm fans. Rpm fan control will claim a product due to having its own pulse width modulation (PWM) control. The GreenStar™ 3 2630 Display, 4200/4600 Gen 4 CommandCenter™ Displays, and 4240/4640 Universal Displays then serve as the operator interface that controls all product application with the air cart.

The John Deere Rate Controller 2000 can be used with Section Control on dry product application equipment. For example, John Deere Rate Controller 2000 growers have the ability to assign dry products with multiple sections up to a total of 16. These 16 sections can be divided up between the active products being applied. For example, if an operator is applying two products, PR1 has eight sections and PR2 has eight sections for a total of 16. With the GreenStar Rate Controller Dry, growers only have the ability to control a single section.

John Deere Rate Controller 2000 is compatible with many different direct injection systems. Depending on the injection pump provider, the user interface could be slightly different.

RAVEN SIDEKICK PRO™ ICD SYSTEM

When using a Raven direct injection system, the John Deere Rate Controller 2000 is only compatible with the Sidekick Pro ICD pump. ICD allows for better integration into the Rate Controller 2000 run pages, enabling rate changes and product enable/disable with ease. Up to four direct injection pumps can be run at one time by the Rate Controller 2000.

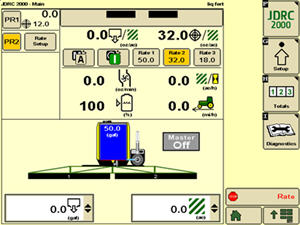

THIRD-PARTY DIRECT INJECTION PROVIDERS

John Deere Rate Controller 2000 is also compatible with other direct injection systems. For example, when using a SureFire system, the Rate Controller 2000 will be set up as a multiple product system and the direct injection pumps will all be setup as additional products. When utilizing other direct injection systems, the rate will be displayed in gallons/acre as seen in the above image.

Sidekick Pro is a trademark of Raven Industries, Inc.

Two application modes are available under liquid fertilizer machine type.

- Liquid slurry dragline continues to record liters/gallons applied but stops counting acres when the master switch is pushed.

- Liquid slurry tanker working like a sprayer profile and suppresses the no flow warning.

Target rates have been increased to 757,082 L/hr (200,000 gph) on the 4200/4600 Gen 4 CommandCenter™ Display and 4240/4640 Universal Display and 757,079 L/hr (199,999 gph) on the GreenStar™ 3 2630 Display.